The Cruiser is a perfect ocean voyager, but simple enough for a quick sail after work. The best word to describe it is easy. Easy to build, sail and maintain.

Design

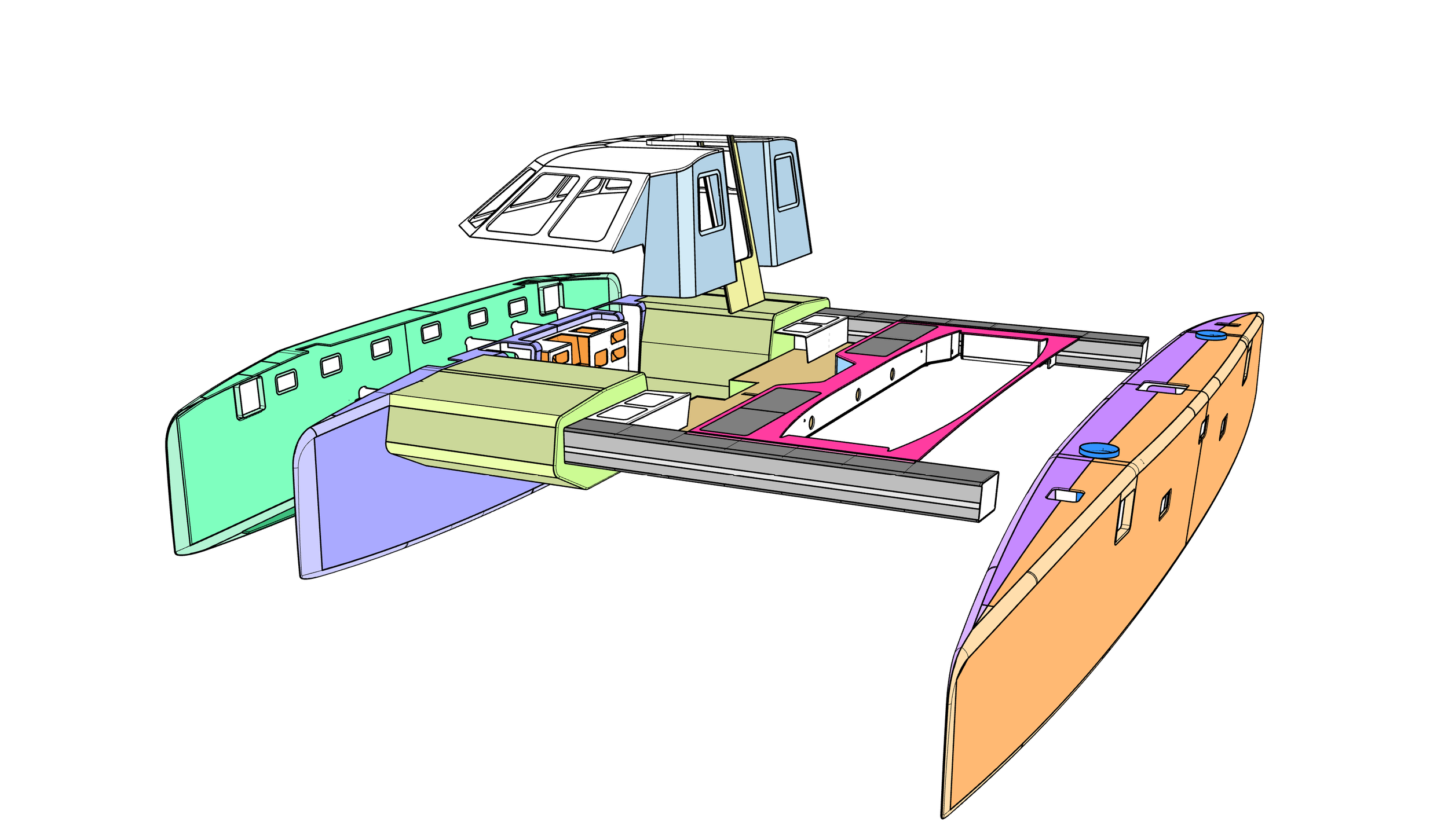

The cruiser is available in a 50 and 60 foot version, the C50 and the C60. They share the same features such as separate cabins and bathrooms, inside and outside steering, large airy saloon, huge outdoor lounging area, shallow draft, minimal gear and large kick up / liftable rudders mounted above the water line.

-

They have a large, simple rig that can be handled by one person without electric winches and totally depowered on any point of sail, with no foredeck work, flogging sheets or expensive deck gear. There is no need to reduce sail at night, worry about uncontrolled gybes or getting in irons and no struggling with jammed headsails at 2 am.

Unlike tacking, shunting does not require boat speed. Therefore, in strong winds, only enough sail is required to propel the boat. The white knuckle element of strong wind sailing is removed.

Layout

The windward hull layout of the C50 and C60 is the same, but the C60 being more spacious in general, it has more seating and payload capacity.

-

Both have two queen size bunks in separate cabins, complete with their own toilet and shower, hanging lockers and plenty of storage space.

The galley is on the same level as the saloon, and shares some of the hull space with the two separate bathrooms. All the plumbing is in one place, saving weight, cost and build time. There is additional, easily accessed storage space in the two saloon table modules, or space for a fridge / freezer.

The seating is divided into two zones for a more flexible use of the space. If one of the tables is occupied for navigation purposes the other is still free. The entry is wide with a sliding roof hatch for easy access to the bridgedeck and improved ventilation. Below deck hatches provide cool air movement on rainy days, making air condition unnecessary.

The lee hull has 2 single bunks in a single or separate cabins, one of which could be made into a shower / toilet or used for storage in the C50. The C60 has a shared bathroom separating the cabins.

Outside there is plenty of space for lounging. A removable awning keeps the entire area shaded if required. A table can be put up on deck to make a large dining area for a late night in the mooring, or at sea without being in the way of the sailing. The fore and aft seating is perfect for watching the scenery go by either in front in the breeze or aft, sheltered by the cabin top watching the wake.

Helm station

One of many unique features of the Cruisers is the helm. A single wheel on a strut that can be rotated to allow inside or outside steering, both with near 360 degree views. The outside location is slightly raised for visibility over the cabin.

-

The winches double as anchor winches. No need to yell at someone on the foredeck to get the anchor up. They are standing right next to the helmsman. And in an emergency, the anchor is dropped without leaving the wheel.

Sheltered seating outside is not required, although a bimini top can be added.

Toy Box

The «toy box» between the beams serves as a huge storage space for diving gear, fenders, ropes, cushions, the outside dining table etc. The toy box also holds the hidden anchor and chain system.

-

There is no need for a chain locker or a heavy windlass. The mooring line is led inside the toy box going from beam to beam before entering one of the two winches. As you pull in the line the chain is stored between the beams before it enters the winch, and the anchor is in place on the roller.

Unstayed masts

The schooner rig makes shunting easy. The rig size makes the boat sailing effortlessly at wind speed, without extras, between 5 and 20 knots, tacking through 90 degrees and no limits on downwind sailing angles because of the unstayed masts.

-

The schooner rig is extremely easy to trim. One line controls the mast bend, foot and leech tension. The required range of adjustment is far smaller than on a boat with a mainsheet track, so a simple 6:1 purchase and cam cleat is sufficient. Some innovative thinking means this control is also used for all three reefing lines, without having to lower the sail to rethread it. The halyards have a simple, fail safe lock on the mast at each reef point. The halyard can be thinner, the mast bending does not alter the halyard tension and internal halyards become feasible, without chafe. Luff tension is provided with a simple block and tackle.

The booms are wishbone booms. These are above head height for safety reasons, are horizontal to minimise windage and have loops of string under them to catch the sail, which is much easier than flaking and lazy jacks. The sheets are lightly loaded as they are not supplying leech tension and lead to the winches at the helm station via blocks on the beams. This ensures that, even if the boat is caught aback, the sails will weathercock, allowing plenty of time and no stress while the boat is steered back on course. Reefing, raising and lowering the sails can be done on any point of sail, in any wind strength, without needing to touch the sail at any stage. The booms are self vanging with a single control line (choker) to adjust leech and foot tension, making the sheet loads significantly less than they are on a conventional rig.

Most multihull sailors reduce sail at night rather than risk being caught in a squall and having to reduce sails which are flogging or pressed hard against the shrouds. The harryproa set up means the boat can be completely depowered by releasing the lightly loaded sheets (no vang loads) and the boat will drift with the sails docile and weathercocked. They can be left like this until the squall passes, be easily reefed or slightly sheeted on to provide steerage speed. The peace of mind from this is enormous.

Further peace of mind comes from the unstayed rigs. There is no need to climb them or remove them to check the fittings, nor any worry about which little piece might break and cause the lot to fall down. An unstayed carbon mast needs no maintenance apart from a coat of paint every 15 years or so. Simple, integral, fail safe halyard locks are standard, reducing the load on the mast and the required halyard size. The halyards and sheets are lead to the winches next to the wheel so all sail handling is done from the security of the cockpit and within easy reach of the helmsman. Sail handling is easy on Visionarry, it is even easier on the Cruisers.

Propulsion

The multipurpose Harryproa Tender is stored between the beams as an integrated part of the deck, attached each end by substantial hinges. By lowering the stern into the water, it becomes the propulsion source for the mothership, saving the weight, cost, maintenance and complexity of a separate engine. By lowering the bow into the water it becomes a large ramp, or it can serve as a bathing platform with easy access to the water.

-

Another advantage of the Harryproa Tender is its size. A seaworthy tender and a wide, stable mothership is the opening up of non marina solutions for overnight visits. Anchoring offshore becomes feasible if you can comfortably motor ashore. Saves the cost of the marina, and guarantees a peaceful night.

When the tender is not in place, a slatted deck or a tramp can cover the gap. The tender is an excellent project to learn about intelligent infusion before starting on the big boat.

Fore and aft rudders and a steerable outboard make manoeuvring with a single outboard a workable proposition, but for those boats which operate in tight spaces, a lightweight, liftable electric outboard could be mounted on a tube next to the helm, providing simple 360 degree thrust to push the boat in any direction.

Building

Harryproas are “intelligently infused” using foam and fiberglass. Intelligent infusion includes as much of the build as possible in the infusion. All the work is done using dry materials in a simple mould which does not require sanding or polishing.

-

What does this mean?

Conventional boat builders build the hull, then the deck in three stages (inner laminate, core and outer laminate) and join them together prior to the fit out which entails trimming and fitting every component, then filletting and tabbing it in place. Everything is then sanded, filled and faired prior to painting.

Intelligent infusion aims to do as much of this as possible using dry, easily cut and handled materials (glass and foam) in easily made low cost moulds. Once everything is prepared, a vacuum bag is placed over it and resin sucked in (infusion). The entire job is wet out, with the perfect amount of resin, no voids and minimal waste. All in one 40 minute shot.

Some of the tasks that can be included in the infusion are: perfectly fitting doors, hatches and windows and all the edging and rebates that these require; landings and edge treatments for the bulkheads, shelves and furniture; male/female joins for the hull components; solids and/or variable laminates and core thicknesses where required.

All surfaces can be ready for painting or gluing, with the option of including fancy (timber, woven carbon, melamine, etc) finishes.

Post infusion, the pieces are all glued together using the slots and joins. Apart from shaping and glassing the polystyrene bow pieces, there is no sanding, grinding or cutting of cured glass, no bogging or fairing and no wet laminating. The time and weight saved are important, the lack of dust, hard work and wastage make building a much more enjoyable job, and one that requires far less skill.

C50 Gallery

C60 Gallery

Specifications

C50 Cruiser

Dimensions

Lw hull 15.00 m / 50′

Ww hull 10.40 m / 34’

Beam 7.76 m / 25′6″

Displacement

Empty 2,000 kg / 4,480 lbs

Payload 2,000 kg / 4,480 lbs

Rm 24 tonne meters

Rig

Mast clearance 16.85 m / 55’4″

Sail area 88 sq m / 946 sq ft

Draft

Rudders up 0.34 m / 13″

Rudders down 2.0 m / 6’8″

Accommodation

Seating in saloon 6 - 8

Berths 6 - 8

Master cabins 2 x queen size bunks, ensuite bathrooms. Option of converting saloon seating to 2 single bunks.

Two single bunks in leeward hull. Optionally one bunk + bathroom or storage space.

-

Composite materials, excluding wastage and overlaps. Allow ~10% for these.

Also excludes bog, paint sandpaper and consumables, all of which will vary between builders.

400 gsm double bias glass: 180 sq m

600 gsm double bias glass: 780 sq m

400 Uni glass: 40 sq m

300 gsm standard modulus carbon uni: 560 sq m

Zoltek 70k carbon tow: 1 x 6 kg spool15mm H80 foam: 40 sq m

20mm H80 foam: 215 sq m

25mm H80 foam: 12 sq m

(Perforated foam if infusion mesh is used, perforated and scored if not)Infusion Resin: 550 kgs, incl 35kgs for glue which will require 2 kgs of colloidal silica.

Peel ply: 650 sq m

C60 Cruiser

Dimensions

Lw hull 18.00 m / 60′

Ww hull 12.40 m / 40′

Beam 8.6 m / 28’

Diplacement

Empty 4,000 kg / 8,800 lbs

Payload 3,000 kg / 6,600 lbs

Rm 32 tonne meters

Draft

Rudders up 0.4 m / 18″

Rudders down 2.0 m / 6’8″

Rig

Mast clearance 19.9 m / 65’4″

Sail area 130 sq m / 1,075 sq ft

Accommodation

Seating in saloon 8-10

Berths 6 - 8

Master cabins 2 x queen size bunks, ensuite bathrooms. Option of converting saloon seating to 2 single bunks.

Two single cabins in leeward hull. Shared bathroom. Optionally one cabin is converted to storage space.

-

Composite materials, excluding wastage and overlaps. Allow ~10% for these.

Also excludes bog, paint sandpaper and consumables, all of which will vary between builders.

300 (or 400) gsm double bias glass: 52 kgs

600 gsm double bias glass: 719 kgs

400 uni glass: 24 kgs

300 gsm standard modulus carbon uni: 377 kgs

Zoltek 70k carbon tow: 1 x 6 kg spool12 mm H80 foam: 19 sq m.

15 mm H80 foam: 24 sq m.

20 mm H80 fom: 152 sq m.

25 mm H80 foam: 60 sq m.

30 mm H80 foam: 26 sq m.(Perforated foam if infusion mesh is used, perforated and scored if not)Infusion Resin: 1,500 kgs

Glue powder: 2 kgs (if making your own)

Filler powder: 10 kgPeel ply: 650 sq m